Environmental Commitment

We don’t just talk about reducing our environmental impact, we are actively investing in new technologies and processes that are making a difference both to the environment and your bottom line.

Contact UsMetalcolor is present worldwide and is one of Europe’s leading suppliers of premium coil coated aluminium coils. Our priority to deliver outstanding customer service drives our efforts in the development of products and personalized delivery concepts.

At Metalcolor, we take our commitment to moving towards more environmentally sustainable aluminium coil coating very seriously. For this reason we have implemented a multitude of measures to reduce our environmental impact.

Our prices do not include any hidden costs. The prices of all our coiled coated products are linked directly to the aluminium prices listed on the LME and Metal premium stock exchanges.

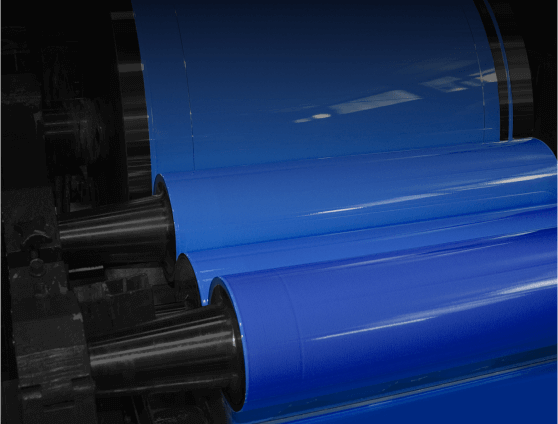

Metalcolor achieves short delivery times by combining 24/7 operations, state-of-the-art coil coating and slitting lines, and customized services tailored to each customer’s needs. This seamless integration ensures efficiency and reliability for every project.

All shipments of our painted aluminium coils are made to measure. Each order will meet your exact requirements and constraints to ensure your production runs smoothly.

Metalcolor was launched as an aluminium coil coating specialist in 1981 in Forel near Lausanne in Switzerland. Right from the beginning our business philosophy was focused on quality and flexibility. Since then, the company has developed enormously with production of pre-lacquered strips increasing from 1 million m2 in 1982 to over 16 million m2 today. Metalcolor has become a reference in the coil coating industry in terms of speed, reliability, flexibility and product range.

Rooted in the Kaizen philosophy, our corporate culture embraces continuous improvement, encouraging a proactive approach to innovation, operational excellence, and long-term value creation.

Metalcolor was the first aluminium coil coating company in Europe to have its own paint mixing facility. Thanks to our unique software, we can quickly produce any colour, regardless of whether it is referenced or not, and recycle excess paint. This autonomy offers us exceptional flexibility in terms of lead times and batch sizes.

Our two coating are equipped with a fast colour changing system that gives us great flexibility in terms of the range and quantities of colours we can provide.Our coil-coating lines have a maximum width of 720 and 420 mm for thicknesses between approximatively 0.18 and 1.50 mm.

In collaboration with our paint and aluminium suppliers, our research and development department regularly creates new applications. Metalcolor follows the aesthetic and technical trends in modern architecture and proposes innovative solutions adapted to your needs.

Each step of the aluminium coil coating process is controlled continuously using the latest testing devices and procedures: XRF spectrometry; Spectrophotometer; Isoscope; Glossmeter and Lineartester.

We don’t just talk about reducing our environmental impact, we are actively investing in new technologies and processes that are making a difference both to the environment and your bottom line.

Contact Us