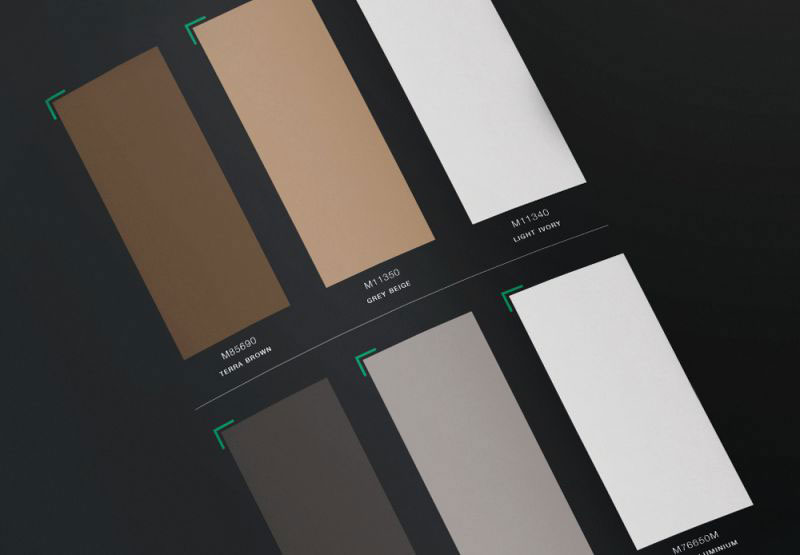

MECOTOUCH our new deep matt and high durable coatings offer functionality and outstanding look! The velvety matt or slightly structured appearance lends itself perfectly to modern architectural trends.

MECOTOUCH is available in an infinite range of colours! These new high-quality surfaces offer excellent mechanical properties and a very high UV resistance. Designed for outdoor use, the sophisticated and elegant appearance also makes them the ideal solution for indoor applications.

Key Features

- Ultra low gloss finish

- Outstanding look

- Very high durable coating

- Velvety matt or slightly structured appearance

Minimum order 100kg

Properties

Polyester (PE)

Polyurethane-Polyamide (PU-PA)

Contact Our Sales Team

Need more information about this product, our sales team in your region will be happy to help you.

Looking for the perfect colour?

We provide custom samples based on your choice of colour or to match an existing product.

Specifications

Description

Basecoat PE (Polyester) + Clearcoat PE

≥ 36 µm

According to EN 13523-1

Ultra Matt 4 U

According to EN 13523-2

± 3 U

According to EN 13523-2

Excellent colour reproducibility

Max deviation

White and pastel colurs: DE* : max 1.0

Red, blue, green, yellow: DE* : max 2.0

Metallic colurs: DE* : max 2.0

Excellent bending properties

No cracking at 1.5 T

No cracking at 1.5 T

According to EN 13523-7

(Depending on alloy and thickness)

Very high UV resistance 10 years warranty1

≥ 50% gloss / DE*: max 5.0

Rural or urban light industrial (or light marine)3

≥ 50% gloss / DE*: max 5.0

Rural or urban light industrial (or light marine)3

According to EN 1396 C.6.3 UV resistance:

RUV4 according to table C.3

2000h UVA: 80% gloss retention

RUV4 according to table C.3

2000h UVA: 80% gloss retention

High corrosion resistance 10 years warranty2

No peeling and no cracking

Rural or urban light industrial (or light marine)3

No peeling and no cracking

Rural or urban light industrial (or light marine)3

According to EN 1396:

C.6.5 Acetic acid salt spray fog resistance,

index 2 according to table C.5

C.6.5 Acetic acid salt spray fog resistance,

index 2 according to table C.5

Description

Basecoat PU (Polyurethane) + Clearcoat PU/PA (Polyurethane Polyamide)

≥ 22 µm

According to EN 13523-1

±10 U to ± 20 U

According to EN 13523-2

± 3 U

According to EN 13523-2

Excellent colour reproducibility

Max deviation

White and pastel colurs: DE* : max 1.0

Red, blue, green, yellow: DE* : max 2.0

Metallic colurs: DE* : max 2.0

Excellent bending properties

No cracking at 0.5 T

No cracking at 0.5 T

According to EN 13523-7

(Depending on alloy and thickness)

Very high UV resistance 10 years warranty1

≥ 50% gloss / DE*: max 5.0

Rural or urban light industrial (or light marine)3

≥ 50% gloss / DE*: max 5.0

Rural or urban light industrial (or light marine)3

According to EN 1396 C.6.3 UV resistance:

RUV4 according to table C.3

2000h UVA: 80% gloss retention

RUV4 according to table C.3

2000h UVA: 80% gloss retention

High corrosion resistance 10 years warranty2

No peeling and no cracking

Rural or urban light industrial (or light marine)3

No peeling and no cracking

Rural or urban light industrial (or light marine)3

According to EN 1396:

C.6.5 Acetic acid salt spray fog resistance,

index 2 according to table C.5

C.6.5 Acetic acid salt spray fog resistance,

index 2 according to table C.5